A heat pump is a system that provides heating and cooling for a building. It transfers heat between the indoors and outdoors instead of generating it directly.

It uses electricity to move heat, making it highly energy-efficient compared to traditional furnaces and air conditioners.

How It Works

A heat pump operates on the refrigeration cycle, similar to a refrigerator or air conditioner:

-

Heating mode: Extracts heat from outside air, water, or ground and transfers it indoors.

-

Cooling mode: Reverses the cycle — extracts heat from indoors and releases it outside.

This reversal is made possible by a

Main Components

-

Compressor – Circulates refrigerant and increases its pressure.

-

Evaporator coil – Absorbs heat from air, ground, or water.

-

Condenser coil – Releases heat into the building (in heating mode) or outdoors (in cooling mode).

-

Expansion valve – Reduces refrigerant pressure before it enters the evaporator.

-

Reversing valve – Switches between heating and cooling modes.

-

Air handler or fan coil unit – Distributes conditioned air throughout the building.

Types of Heat Pumps

-

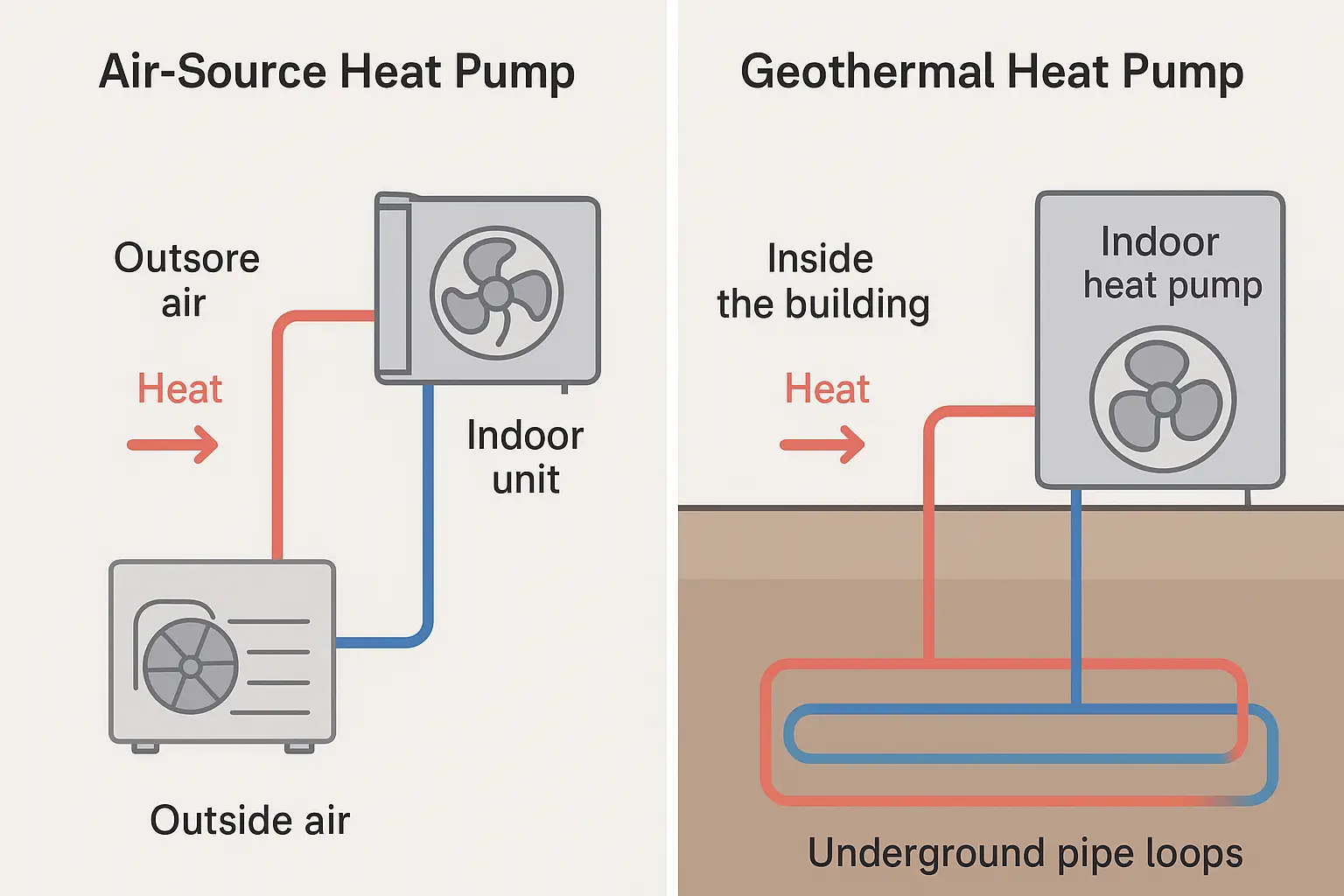

Air-Source Heat Pumps (ASHP)

-

Extract heat from outside air.

-

Most common for residential and light commercial use.

-

Modern versions work even in sub-freezing temperatures.

-

-

Ground-Source or Geothermal Heat Pumps (GSHP)

-

Transfer heat to/from the ground or groundwater.

-

Very efficient but costly to install due to underground piping.

-

Ideal for large buildings or campuses.

-

-

Water-Source Heat Pumps (WSHP)

-

Use a water loop system — often seen in multi-story or multi-zone buildings.

-

Each zone unit can independently heat or cool as needed.

-

-

Hybrid Systems

-

Combine heat pumps with gas furnaces or boilers for efficiency in extreme cold.

-

Efficiency Metrics

-

COP (Coefficient of Performance) – Heating efficiency (ratio of heat output to electrical input).

The Coefficient of Performance (COP) is a key measure of efficiency for heating and cooling systems such as heat pumps, air conditioners, and refrigerators. It tells you how much heating or cooling you get per unit of energy consumed

COP =

Useful Heating or Cooling Output (kW)

/Energy Input (kW) - EER / SEER (Energy Efficiency Ratio / Seasonal Energy Efficiency Ratio) – Cooling efficiency.

-

HSPF (Heating Seasonal Performance Factor) – Seasonal heating efficiency.

Higher numbers mean better efficiency.

Applications in Buildings

-

Residential: Air-source systems with ducted or ductless (mini-split) configurations.

-

Commercial: Water-source heat pumps connected to a central loop.

-

Institutional / Large Buildings: Geothermal or variable refrigerant flow (VRF) systems.

Benefits

-

-

Lower operating costs (especially with electricity or renewable power).

-

Reduced greenhouse gas emissions.

-

Provides both heating and cooling in one system.

-

Requires less maintenance than combustion systems.

-

Challenges

-

High upfront installation cost.

-

Efficiency can drop in extreme cold (for air-source systems).

-

Requires proper design and sizing to avoid performance issues.

Modern Innovations

-

Variable-speed compressors (inverter technology) for smoother operation.

-

Smart controls and zoning for better comfort and efficiency.

-

Integration with renewable energy (solar PV, thermal storage).

-

CO₂ and natural refrigerants replacing older high-GWP refrigerants.

Let’s compare Air-Source Heat Pumps (ASHP) and Geothermal (Ground-Source) Heat Pumps (GSHP) side by side so you can see how they differ in performance, cost, and applications:

Comparison: Air-Source vs Geothermal Heat Pumps

| Feature | Air-Source Heat Pump (ASHP) | Geothermal Heat Pump (GSHP) |

|---|---|---|

| Heat Source / Sink | Outside air | Ground or groundwater |

| How It Works | Extracts heat from the outdoor air in winter and releases heat outdoors in summer. | Transfers heat to or from the earth through buried pipe loops or wells. |

| Installation Location | Outdoor unit + indoor air handler (similar to an AC). | Indoor unit + underground piping loop (horizontal or vertical). |

| Installation Cost | Lower initial cost — typically £4,000–£10,000 for a residential system. | Higher cost — typically £10,000–£30,000, depending on drilling or trenching required. |

| Operating Efficiency (COP) | 2.0–4.0 (depending on outdoor temperature). | 3.5–6.0 (more stable since ground temperature is constant). |

| Performance in Cold Weather | Efficiency drops in freezing conditions; may require electric or gas backup heat. | Consistent performance year-round; not affected by outdoor air temperature. |

| Energy Source | Electricity only. | Electricity only, but more efficient due to stable ground temps. |

| Maintenance | Easier to access for servicing; outdoor unit exposed to weather. | Underground loops are low-maintenance, but repairs (if needed) are more complex. |

| Lifespan | 15–20 years for the heat pump; 10–15 years for outdoor components. | 20–25 years for the heat pump; 50+ years for underground piping. |

| Environmental Impact | Lower emissions than fossil fuel systems, but less efficient in extreme cold. | Very low emissions; can cut energy use by 40–70%. |

| Space Requirements | Needs outdoor space for the air unit and possibly ductwork. | Requires land or drilling area for loop installation. |

| Best Suited For | Mild to moderate climates; retrofit projects. | New construction or sites with sufficient land or drilling access; large buildings. |

Summary

-

Air-Source Heat Pumps

Lower upfront cost

Easier to install (especially for existing buildings)

Efficiency declines in very cold weather -

Geothermal Heat Pumps

Much higher efficiency and stability

Lower long-term operating costs

High initial installation cost and site-specific feasibility

Typical Applications

-

ASHP: Houses, apartments, small offices — where outdoor air units are feasible.

-

GSHP: Schools, hospitals, commercial buildings, or homes with land for ground loops.

Example Efficiency Impact

If electricity costs £0.15/kWh:

-

An air-source system might yield £400–£800/year heating savings vs. resistance heating.

-

A geothermal system could double that, saving £800–£1,600/year, often paying back the extra installation cost in 5–10 years.